SPIE AL 2023

Markets

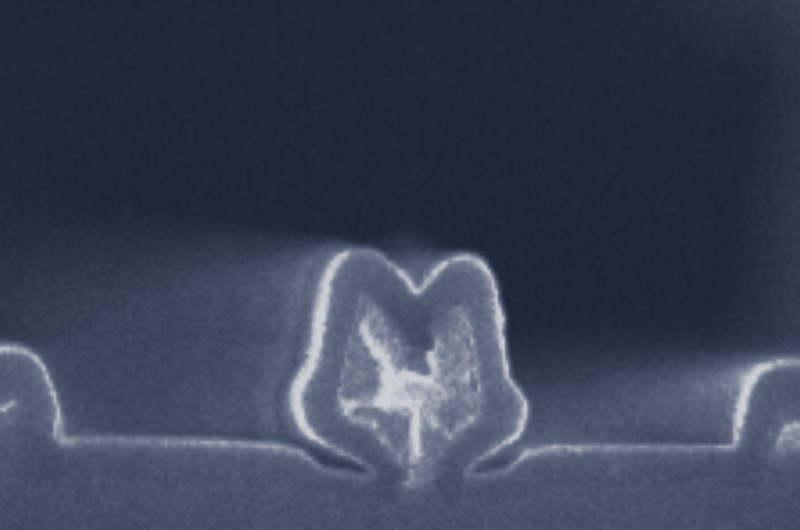

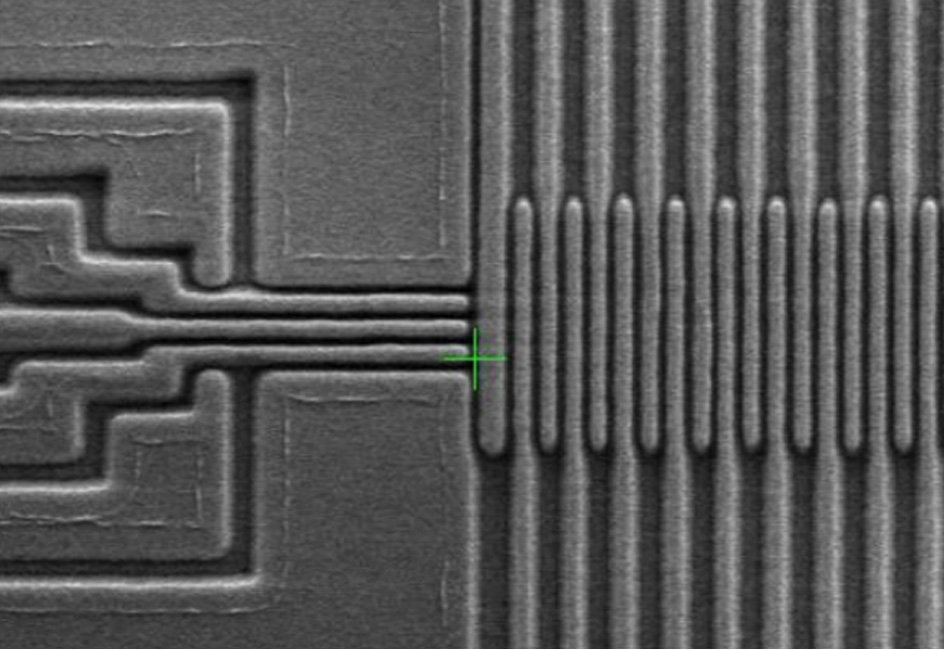

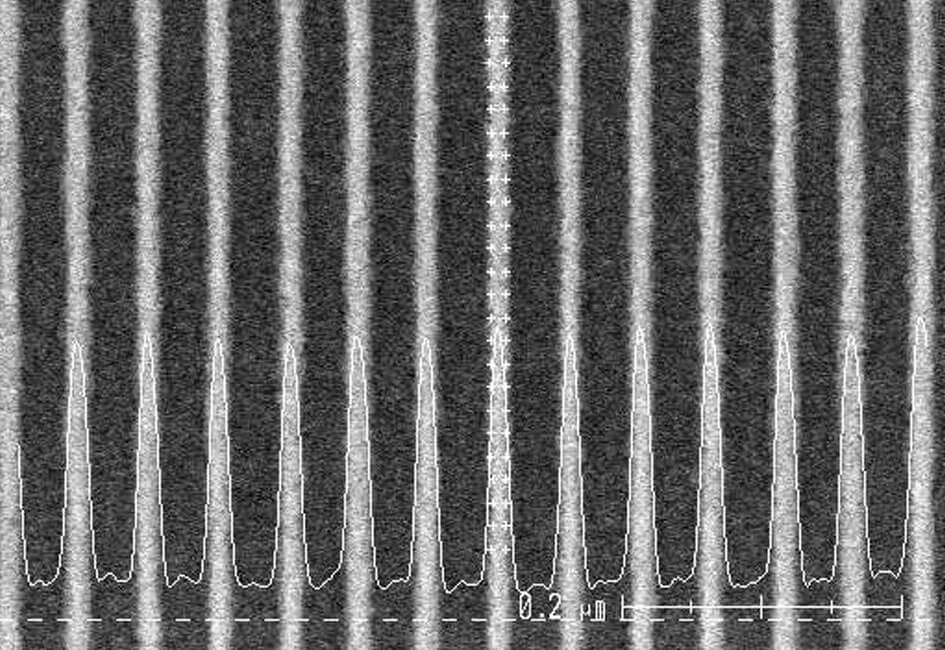

Electron Beam Lithography is a key enabling technology for both Semiconductor and Micro/Nano fabrication. With Variable Shaped Beam technology and a high degree of automation, our systems are tailored for use in applied research and industrial production, where reproducible and fast exposures of entire substrates or stacks with high quality are required.

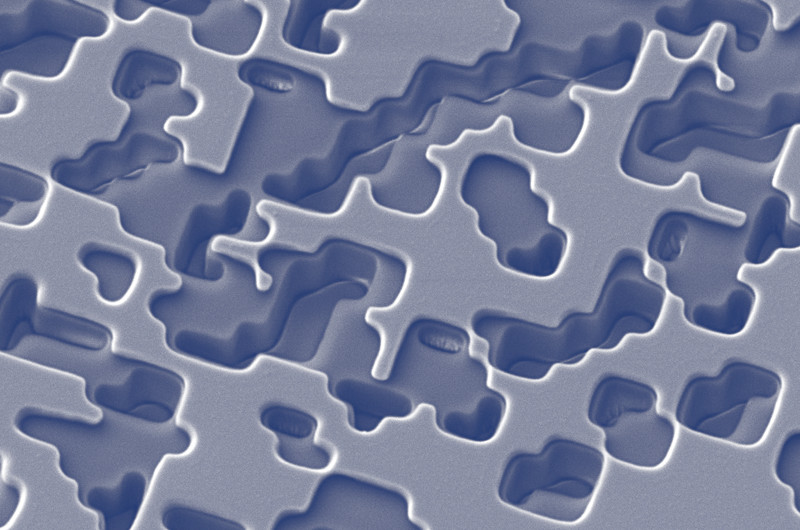

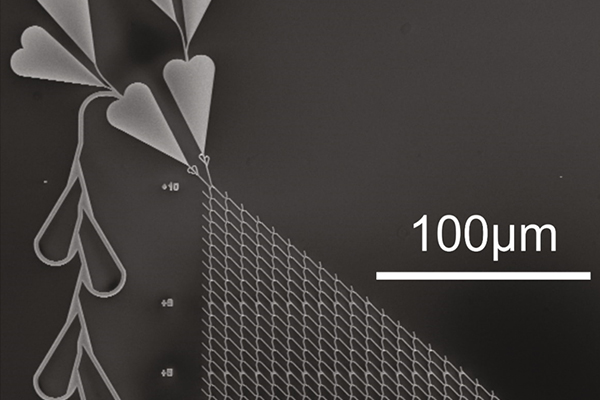

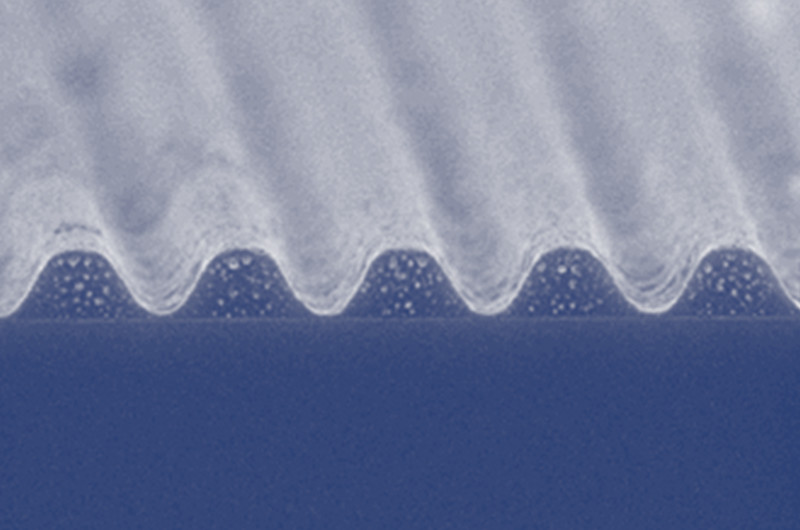

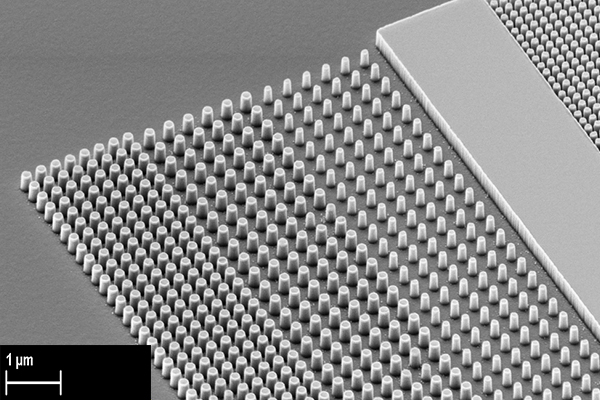

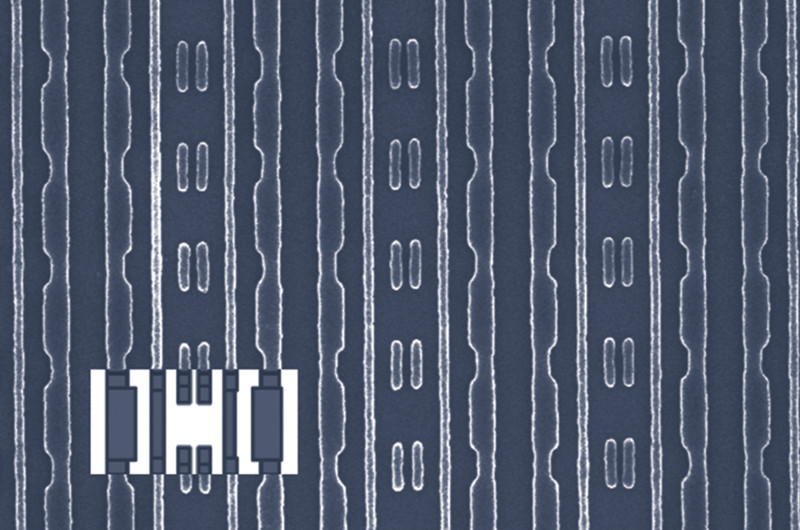

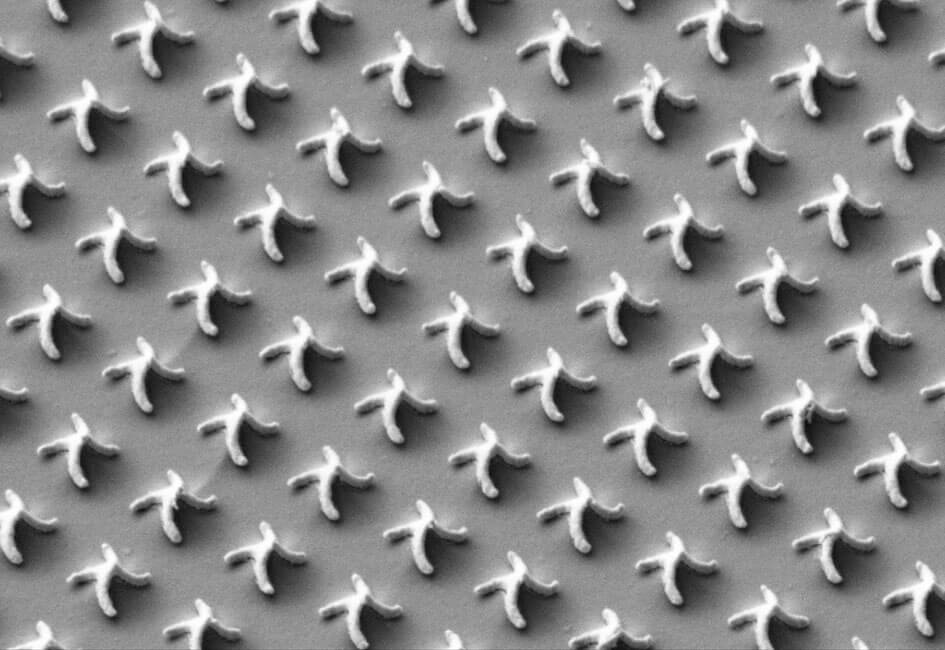

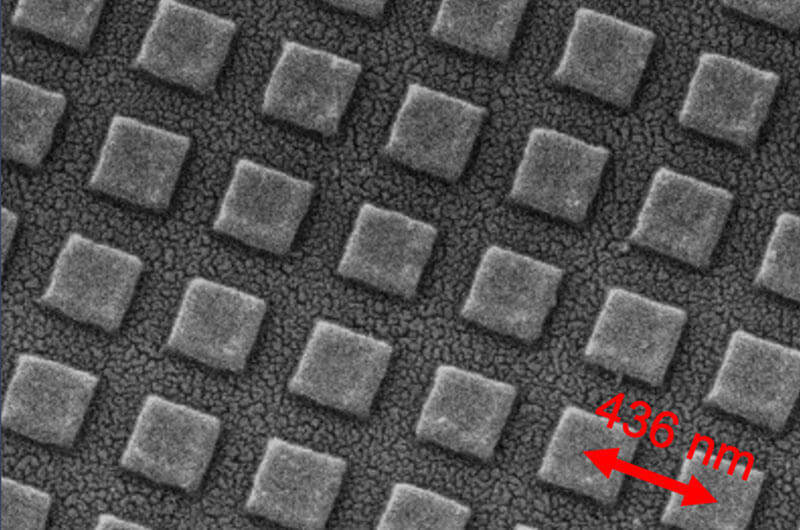

Applications range from micro- and nanoelectronics to integrated optics and photonics to nano- and biotechnology. Arbitrary layouts can be written directly on wafers or masks with high resolution, e.g. microelectronics circuits, diffractive optical elements, or metamaterials.

Efficient data processing & extended strategies open up new applications, especially in the field of AR/VR.

Maskless writing with the electron beam enables high flexibility to generate new devices, small volume production, writing of critical features in multilayer devices, or generation of templates for mass production.

Our lithography systems are mainly used in three markets

Compound Semiconductor

Our lithography systems are capable to directly pattern a huge variety of compound semiconductor materials with high reliability & stability which are needed in 24/7 production environments. Moreover, we offer the flexibility to use different substrate types at our machines and fully automated handling and alignment procedures for overlay exposures.

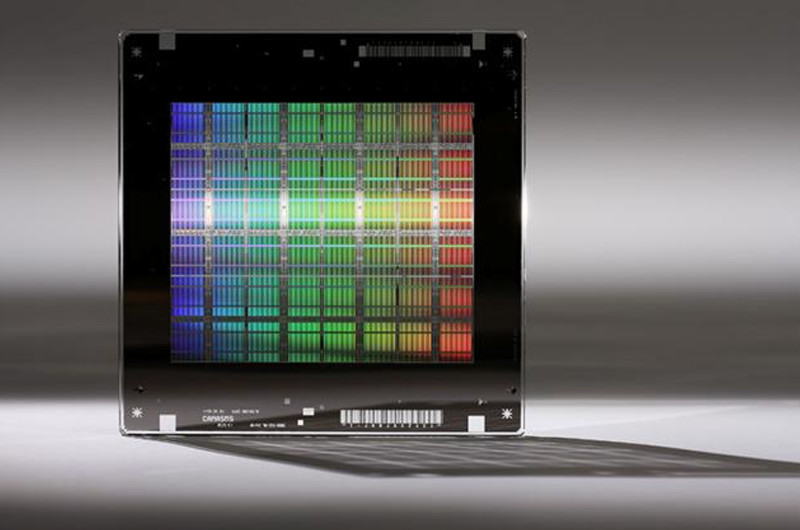

Mask and Glass

We provide e-beam lithography systems for industrial mask makers. Moreover, micro-optical elements can be patterned onto glass substrates with excellent quality and high accuracy. Another application is template writing to enable mass production of small structures, e.g. for metasurfaces, on large areas.

Advanced Research

Our customers in research institutions typically operate multi-user facilities. They use our electron beam lithography systems to manufacture devices for multiple emerging applications like quantum computing, MEMS/NEMS technology or biosensing. The high flexibility of the Vistec systems and the capability for efficient writing on large areas are of particular importance for our customers.

Applications

Publications

-

-

JM3 Vol.22 Issue 04/2023

-

JM3 Vol.22 Issue 04/2023