Our customer support every step of the way

Vistec supports customers all the way – from the early evaluation phase of a possible system procurement to preparing a beneficial operation environment, from training of engineering personnel to optimization of the customer’s lithography process and reliable efficient long-time operation.

-

Vistec customer care

FROM EARLY PLANNING TO LONG-TIME OPERATION

-

Overview

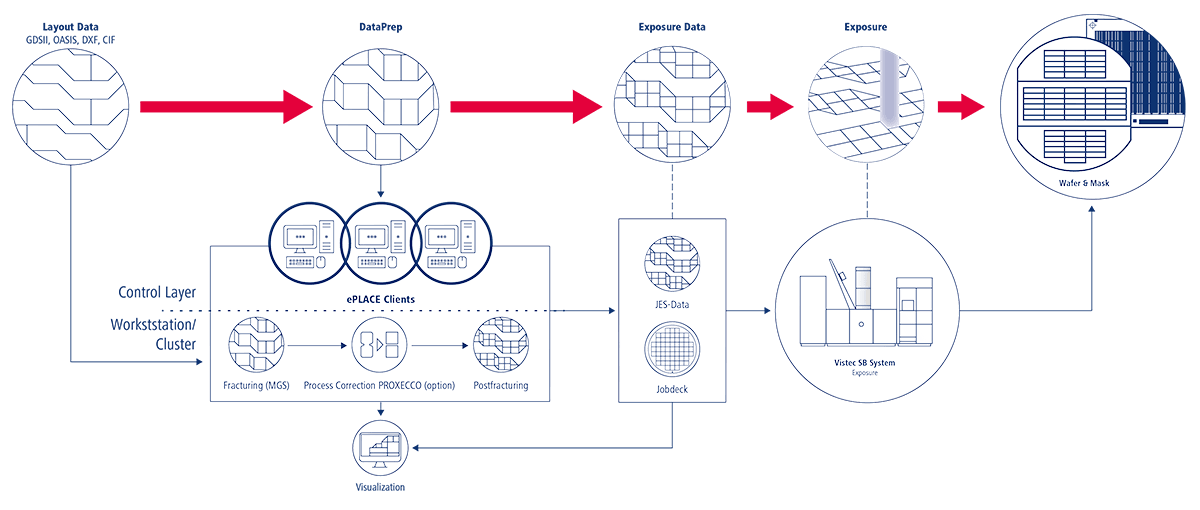

Vistec Electron Beam offers a dedicated data preparation software and hardware package, which is perfectly tailored to the specific requirements of its Variable Shaped Beam systems. Customized high performance computing hardware, combined with Vistec’s innovative software programs ePLACE and PROXECCO, enables fitted fracturing and correction algorithms for fast and accurate data processing in applied research as well as industrial applications.

PROXECCO and ePLACE are licenced by Vistec Electron Beam GmbH.

Application support is offered for the complete data preparation software.

ePLACE

ePLACE (e-beam direct write and mask data Preparation layout console.) is a powerful and comprehensive software product for layout data processing and optimization which has been specifically adapted to Vistec’s Variable Shaped Beam systems.

Proximity Effect Correction

PROXECCO is a software package which provides leading edge Proximity Effect Correction (PEC) for electron-beam lithography systems. PROXECCO is fully integrated into the ePLACE package and consequently meets the same reliability and performance requirements.

-

Overview

Vistec systems offer high uptime proven reliability in 24/7 operation. Long-time stability and performance are ensured by regular preventive maintenance, conducted by Vistec field service.

Vistec provides field service for systems running worldwide. During the warranty time Vistec provides technical assistance, maintenance and repair work to ensure system availability. Benefit from different coverage models for after-warranty field service regarding hardware, software, and work performed, up to a full service contract and on-site engineering personnel.